Plastic Tube Filling Sealing Machine Cream Ointment Filling: Working Principle

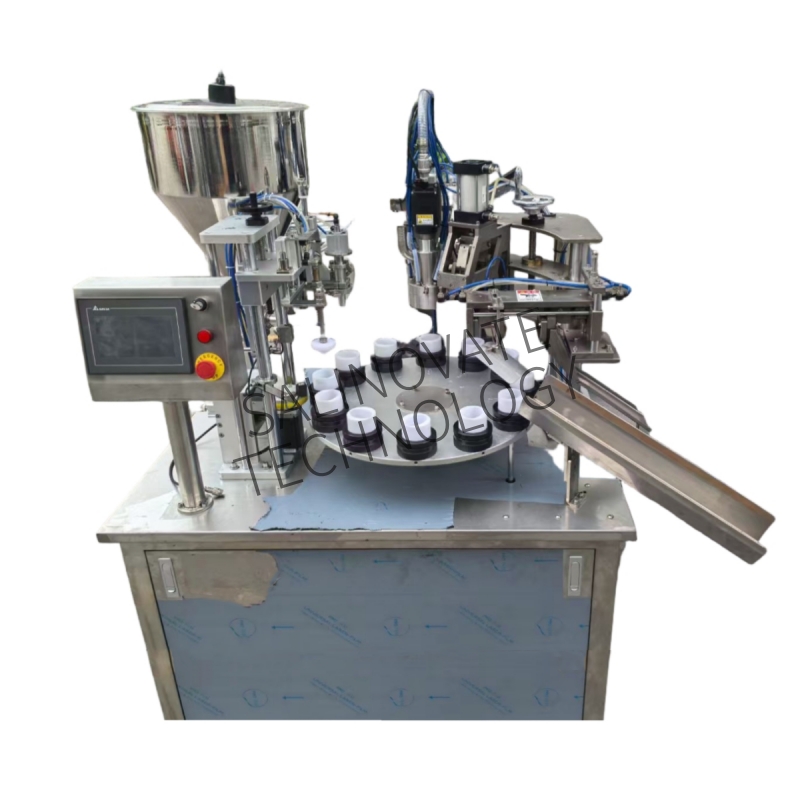

The whole tube filling sealing machine is driven by electricity, PLC touch screen control. The tube feeding can be designed manually insert in to save the cost or designed automatically with the automatic feeding hopper to accelerate the production.

The color mark orientation device help to ensure the color mark of the tube at the right position then after sealing the mark is in the middle.

After the tube feeding and color mark orientation, the machine conducts the filling job, heat sealing job(cooling together with this part in case of the overheating), trimming, code moulding and then tube discharging job.

Plastic Tube Filling Sealing Machine Cream Ointment Filling: Features

1)Filling volume: 5-20ml/15-150ml/20-200ml/30-300ml

2)Acceptable tube type: plastic tube/laminated tube

3)Tube diameter range: 13-50mm

4)Tube height range: 80-220mm

5)Compressed air: 0.4-0.6MPa(prepared by the user)

Plastic Tube Filling Sealing Machine Cream Ointment Filling: Application

Cosmetic cream and ointment, pharmaceutical ointment, etc are often adopt plastic tube package. This type machine can help fill the cream and ointment products into such tubes and have a heat sealing. Special shaped tube sail is supported such as sector shaped tail.